Depositors

The Depositor range has been designed to suit the needs of the Bakery, Confectionery and Food Service Industries as well as having applications in the Pharmaceutical and other sectors. Each model has the capability of depositing numerous products such as cake batter, muffin batter, sponge batter, fruited batter, fruit fillings with particulates, jams & marmalades, custards, chocolate compounds, fondants, pastry doughs, bread doughs, cream fillings, meat fillings, sauces, liquids, pastes and many other items.

With three models 35, 65 and 95 means that production requirements for the Artisan or small start-up unit, to medium producers and through to industrial levels can all be met. Multihead models are also available.

Choice of hopper capacity, varying deposit speeds, four different product cylinder sizes and a very wide range of outlets operated via a foot actuator pedal, make this is an extremely versatile range. As an alternative to fixed outlets a hand gun is available in 25mm or 38mm attached to the depositor via a 1.5 metre silicon hose. Use of tri clover clamps allows easy and quick change over of attachments. All the depositors have been designed with the user in mind for ease of operation maximisation of production time and strip down for cleaning. Variable deposit speed and the REACH rotary D valve gives the benefit of high accuracy and great versatility.

All the units are produced in brush finished stainless steel, with FDA approved Food Grade plastics used where appropriate. Global partnership with and use of SMC pneumatics means that world-wide product support is readily available.

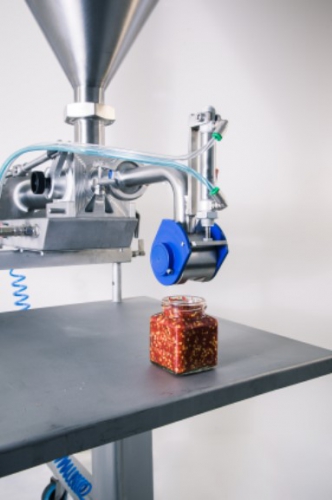

Rise & Fall Multifunctional Depositors

Mounted on a pneumatically operated mast which takes the depositor to a low level for filling and then elevates the depositor to a convenient working height. The mast is manufactured from stainless steel and is mobile so that the unit can be easily manoeuvred into position. The machine has application in a variety of operations as it can be used as a stand-alone unit or positioned alongside an indexing line.

As a stand-alone unit the depositor has an adjustable table to take trays, tins, acetates or a variety of other receptacles.

Alternatively it can be positioned alongside a fixed table. Fixed outlets or the handgun delivery are options as are the choice of product cylinders.

Versatiltity & Modularity

All the depositors can be bridge mounted over a conveyor line. The 65 or 95 models can also be mounted on a fixed height mast to be stationed alongside conveyor lines. Additional units are added as production capacity increases. Continuous production is achieved by pumping product into the depositor hopper.

Table Top Depositors

For the production unit where space is tight we offer all three models the 35, 65 & 95 as table top units. The 35 is available only with a 19 litre hopper. The 65 has a choice of a 19 litre or 60 litre hopper and the 95 has the 60 litre hopper. All three machines will operate with easily interchangeable 38mm, 50mm & 63mm product cylinders with a 75mm cylinder option for the two larger machines.

The full fixed outlet range or handgun will fit all three machines.

Low Level Depositor

The 65 and 95 model is also produced as a Low Level Depositor. It is mounted on a stainless steel mobile frame and comes with a choice of 19 - 120 litre hoppers. The unit lends itself to being positioned at the side of an indexing line with a fixed swan neck depositing pipe, or stationed over the conveyor for decorating or filling of products.

As an alternative delivery method the hand gun option can be fitted and a table option is also available.

Industrial Depositor Head

For very high volume industrial applications the model 95IM is an ideal solution. Mounted on an extremely sturdy stainless steel frame that fits over an index conveyor, the unit has a hopper of 250 litres which can be filled via a tipping mixer, bowl tipper or transfer pumps. The hopper feeds a variable number of depositing heads dependant on conveyor width and deposit weights. The number of depositing heads in operation at any one time is operator controlled and distance between heads is easily adjusted giving the unit flexibility and versatility.

Mitsubishi controllers and SMC pneumatics and actuation systems ensure a high quality unit with world-wide back up.

Each system is designed to meet individual customer needs.

Group of companies

Group of companies